Lugand Aciers

85 route de Château Covet 01100 GROISSIAT

Tel. :+33(0)4.74.81.91.50 | info@lugand-aciers.com

Notre catalogue est mis régulièrement à jour. Afin de vous assurer d’avoir la dernière version, nous vous invitons à vous inscrire aux alertes, afin d’être prévenu par email d’une nouvelle version disponible sur cette page.

| LUGAND ACIERS | AFNOR | W.Nr | EN | AISI/SAE/ASTM | GOST | JIS | GB | Page |

|---|---|---|---|---|---|---|---|---|

| S235JR | E24-2 | 1.0037 | 15 | |||||

| E335 | A60-2 | 1.0060 | 16 | |||||

| LA2067 | 100C6 | 1.2067 | 102Cr6 | L3 | WX15 | Cr12 | 17 | |

| LA1744 | XC75 | 1.1248 | C75 | Y7-Y | T7 | 19 | ||

| LA1730 | XC48 | 1.1730 | C45+N | 1045 | 45 | S45C | 45# | 20 |

| LA7225 | 42CD4 +QT | 1.7225 | 42CrMo4 +QT | 4140 | 40XMO | SCM440H | 24 | |

| LA2312 | 40CMD8S +QT | 1.2312 | 40CrMnMoS8.6 +QT | P20+S | 40X2RM-Y | P20 | 4Cr2Mn1MoS | 25 |

| LA2311 | 40CMD8 +QT | 1.2311 | 40CrMnMo8.6 +QT | P20 | 40X2RM | P20 | 4Cr2Mn1Mo | 28 |

| LA2738 | 40CMND8.6 +QT | 1.2738 | 40CrMnNiMo8.6.4 +QT | P20+Ni | 40X2RHM | 3Cr2NiMo | 30 | |

| LA2714 | 55NCDV7 +QT | 1.2714 | 55NiCrMoV7 +QT | 6LF3 | 5XH2MO | 5CrNiMoV | 32 | |

| SMV3O | EZ38CDV5.1 +QT | 1.2343 ESU | X38CrMoV5.1 ESR +QT | H11ESR | 4X5MOC-W | SKD6 | 33 | |

| APXV | Z15CN 16.02 +QT | 1.4057 | X17CrNi 16.2 | 431 | 17X16H2 | 34 | ||

| APX4 | Z8CND17.04 +QT | 1.4418 | X4CrNiMo 16.5.1 | 35 | ||||

| LA2316 | Z35CD17 +QT | 1.2316 | X38CrMo16 +QT | 420 | 40X16M | 3Cr17Mo | 36 | |

| LA2099 | Z7CS13+QT | 1.2099 Mod | X7CrS13+QT | 416 Mod | 37 | |||

| LA2085 | Z30CS16 +QT | 1.2085 | X33CrS16 +QT | 3Cr17+S | 38 | |||

| LA2767 | 40NCD16 | 1.2767 | 45NiCrMo16 | 6F7 | 45X2H4M | 45CrNi4Mo | 39 | |

| 819AW | E35NCD16H | 1.6773 ESU | 35NiCrMo16 ESR | 42 | ||||

| LA2343 | Z38CDV5.1 | 1.2343 | X38CrMoV5.1 | H11 | 4X5MOC | SKD6 | 4Cr5MoSiV | 43 |

| LA2343ESR | EZ38CDV5.1 | 1.2343 ESU | X38CrMoV5.1 ESR | H11ESR | 4X5MOC-W | SKD6 | 46 | |

| SMV3W | EZ38CDV5.1 | 1.2343 ESU | X38CrMoV5.1 ESR | H11ESR | 4X5MOC-W | SKD6 | 47 | |

| ADC3W | EZ35CDV5.1 | 1.2340 ESU | X35CrMoV5.1ESR | H11 ESRMod | 49 | |||

| LA2344 | Z40CDV5.1 | 1.2344 | X40CrMoV5.1 | H13 | 4X5MO1C | SKD61 | 4Cr5MoSiV1 | 51 |

| LA2344ESR | EZ40CDV5.1 | 1.2344 ESU | X40CrMoV5.1 ESR | H13ESR | 4X5MO1C-W | SKD61 | 52 | |

| ADC88 | EZ36CDV5.2 | 1.2367 Mod ESU | X35CrMoV5.2 ESR | 53 | ||||

| SMV5W | EZ50CDWV5 | X50CrMoWV5 ESR | 54 | |||||

| LA2083 | Z40C13 | 1.2083 | X40Cr14 | 420 | 46X13 | SUS420J2 | 4Cr13 | 55 |

| X13T6W | EZ40CD14 | 1.2083 ESU | X40CrMo14 ESR | 420 ESR | 46X13-W | SUS420J2 | 57 | |

| XDBDW | EZ100CD17 | 1.3544 ESU | X105CrMo17 ESR | 440C ESR | 110X17-W | 58 | ||

| X15TN | EZ40CDVN16.2 | 1.4123 ESU | X40CrMoVN16.2 ESR | 59 | ||||

| MLX17 | EZ1CNDAT 12.11.2 | 1.4612 ESU | X1CrNiMoAlTi 12.11.2 ESR | 60 | ||||

| LA2249 (V300) | 45SCD6 | 1.2249 | 45SiCrMo6 | 45XCO | 63 | |||

| MARVAL 18 | E Z2 NKD18 | 1.6359 | X2NiCoMo18-8-5 | 64 | ||||

| LA7765 (GKH) | 32CDV13 | 1.7765 | 32CrMoV13 | 61 | ||||

| LA8509 (LK3) | 40CAD6.12 | 1.8509 | 40CrAlV6.12 | 62 | ||||

| LA166 | 16NC6 | 1.5919 | 16NiCr6 | 65 | ||||

| LA2162 | 20MC5 | 1.2162 | 21MnCr5 | 20XR | 20CrMn | 66 | ||

| LA4307 | Z2CN18.9 | 1.4307 | X2CrNiMo18.09 | 304L | 03X18H9 | SUS304L | 0Cr18Ni10N | 67 |

| LA4404 | Z2CND17.12.2 | 1.4404 | X2CrNiMo18.12.03 | 316L | 03X17H12M2 | SUS316L | 0Cr17Ni10Mo2N | 68 |

| LA2842 | 90MCV8 | 1.2842 | 90MnCrV8 | O2 | 9R2O | 9Mn2V | 69 | |

| LA2379 | Z160CDV12 | 1.2379 | X153CrMoV12 | D2 | X12MO | SKD11 | Cr12Mo1V1 | 73 |

| LA3343 | Z85WDCV6.5.4.2 | 1.3343 | HS 6.5.4.2 | M2 | P6M5 | SKH51 | W6Mo5Cr4V2 | 77 |

| LA3247 | Z110DKCWV9.8.4.2.1 | 1.3247 | HS 2.9.1.8 | M42 | SKH59 | W2Mo10Cr4V1Co8 | 79 | |

| LAPM2023 | Z130WDCV6.5.3 | 1.3395 | HS 6.5.3 | M3:2 | P6M5O3-MN | SKH53 | 81 | |

| LAPM2030 | Z130KWDCV8.6.5.3 | HS 6.5.3.8 | P6M5O3K8-MN | 82 | ||||

| LAPM2053 | 1.3352 | HS 4.3.8 | 83 | |||||

| LAPMAPZ10 | Z115CDVN19.2.1 | X115CrMoVN19.2.1 | 84 | |||||

| LA1050 | 1050A | 3.0255 | AL99,5 | 1050A | 86 | |||

| LA2017 | 2017A | 3.1325 | AlCu4MgSi(A) | 2017A | 87 | |||

| LA5083 | 5083 | 3.3547 | AlMg4, 5 Mn0,7 | 5083 | 88 | |||

| LA7000C | 7021 | AlZn5,5 Mg1,5 | 89 | |||||

| LA7022 | 7022 | 3.4335 | AlZn4,5 Mg3Cu | 7022 | 91 | |||

| LA7075 | 7075 | 3.4365 | AlZn5,5 MgCu | 7075 | 90 | |||

| Cuivre | CuC1 | W008A | 93 | |||||

| LAKAL | W Cu | 98 | ||||||

| Laiton CuZn39Pb2 | UZ40Pb2 | 2.0332 | CuZn39Pb2 | C37700 | C3713 | 95 | ||

| Laiton CuZn40Pb3 | UZ36Pb3 | 2.0375 | CuZn40Pb3 | C37700 | C3713 | 95 | ||

| LAUE12P | UE12P | 2.1052 | CuSn12 | C90800 | 96 | |||

| LAUA10N | UA10N | 2.0966 | CuAl10Ni5Fe4 | C63000 | 97 |

| Lugand Aciers | AFNOR | EN | WNr | DIN | AISI/SAE/STM | GOST | JIS |

| Etiré doux | E24-2 | S235JR | St37-2 | ||||

| Etiré mi-dur | A60-2 | E335 | St60-2 | ||||

| Tôle Bleue | XC75 | C75 | 1.1750 | 1075 | |||

| LA 2067 | Y100C6 | 100Cr6 | 1.2067 | L3 | |||

| LA 1730 | XC48 | C45U | 1.1730 | 1045 | 45 | S45C | |

| LA 7225 | 42CD4 | 42CrMo4 | 1.7225 | 42CrMo4 | 4140 | 40X | SCM440H |

| LA 2312 | 40CMD8S | 40CrMoS8.6 | 1.2312 | 40CrMoS8.6 | P20+S | P20 | |

| LA 2311 | 40CMD8 | 40CrMo7 | 1.2311 | 40CrMo7 | P20 | P20 | |

| LA HR300 | 40CMD8Mod | 40CrMo7Mod | 1.2311Mod | 40CrMo7Mod | P20Mod | ||

| LA 2738 | 40CMND8.6 | 40CrNiMo8.6.4 | 1.2738 | 40CrNiMo8.6.4 | P20+Ni | ||

| LA 400+ | 40CMND8Mod | 40CrNiMo8.6.4 Mod | 1.2738Mod | 40CrNiMo8.6.4 Mod | P20+NiMod | ||

| LA 2714 | 55NCDV7 | 55NiCrMoV7 | 1.2714 | 55NiCrMoV7 | 6LF3 | ||

| LA 2343 ESRHH | E-Z38CDV5 | X38CrMoV5.1 ESR | 1.2343ESU | X38CrMoV5.1 ESU | H11ESR | 40X5 | SKD6 |

| SMV3O (LA2343O) | E-Z38CDV5T | X38CrMoV5.1 ESR | 1.2343ESU | X38CrMoV5.1 ESU | H11ESR | 40X5 | SKD6 |

| LA 2767 | 40NCD16 | 45NiCrMo16 | 1.2767 | 45NiCrMo16 | 6F7 | ||

| LA 2767ESR | E-40NCD16 | 45NiCrMo16 | 1.2767ESU | 45NiCrMo16 ESU | 6F7 ESR | ||

| 819AW | E-35NCD16H | 35NiCrMo16 ESR | |||||

| LA 2343 | Z38CDV5 | X38CrMoV5.1 | 1.2343 | X38CrMoV5.1 | H11 | 40X5 | SKD6 |

| LA 2343ESR | E-Z38CDV5 | X38CrMoV5.1 ESR | 1.2343 ESU | X38CrMoV5.1 ESU | H11 ESR | 40X5 | SKD6 |

| LA 2344 | Z40CDV5 | X40CrMoV5.1 | 1.2344 | X40CrMoV5.1 | H13 | SKD61 | |

| LA 2344ESR | E-Z40CDV5 | X40CrMoV5.1 ESR | 1.2344 ESU | X40CrMoV5.1 ESU | H13 ESR | SKD61 | |

| SMV3W | E-Z38CDV5 | X38CrMoV5.1 ESR | 1.2343 ESR | X38CrMoV5.1 ESU | H11 ESR | 40X5 | SKD6 |

| ADC3W | E-Z35CDV5 | X35CrMoV5.1 ESR | 1.2340 ESR | X36CrMoV5.1 ESU | H11 ESR Mod | H11 ESR Mod | |

| ADC88 | E-Z36CDV5.2 | X35CrMoV5.2 ESR | 1.2367 ESR Mod | ||||

| SMV5W | E-Z50CDWV5 | X50CrMoWV5 ESR | |||||

| LA 2085 | Z30CS16 | X33CrS16 | 1.2085 | X33CrS16 | |||

| LA 2099 | Z7CS13 | X7CrS13 | 1.2099 | X7CrS13 | |||

| LA 2083 | Z40C13 | X40CrMo14 | 1.2083 | X40CrMo14 | 420 | 40X13 | SUS420J2 |

| LA 2316 | Z40CD16 | X40CrMo16 | 1.2316 | X40CrMo16 | 420 Mod | ||

| XDBDW | E-Z100CD17 | X105CrMo17 ESR | 1.2083 ESU | X40CrMo14 ESU | 420 ESR | 40X13 | SUS420J2 |

| X15TN | E-Z40CDVN16.2 | X40CrMoVN16.2 ESR | 1.3544 ESU | X105CrMo17 ESU | 440C ESR | ||

| LA 4307 | Z2CN18.9 | X2CrNi18.09 | 1.4307 | X2CrNiMo18.09 | 304L | 03X18H11 | SUS304L |

| LA 4404 | Z2CND18.10 | X2CrNiMo 18.12.03 | 1.4404 | X2CrNiMo 18.12.03 | 316L | 03X17H 14M3 | SUS316L |

| LA 7765 (GKH) | 32CDV13 | 32CrMoV13 | 1.7765 | 32CrMoV13 | |||

| LA 8509 (LK3) | 40CAD6.12 | 40CrAlV6.12 | 1.8509 | 40CrAlV6.12 | |||

| LA 2249 (V300) | 45SCD6 | 45SiCrMo6 | 1.2249 | 45SiCrMo6 | |||

| LA 166 | 18NC5 | 18NiCr5.4 | 1.5810 | 16NiCr6 | |||

| LA 2162 | 20MC5 | 21MnCr5 | 1.2162 | 21MnCr5 | 22K | ||

| LA 2842 | 90MCV8 | 90MnCrV8 | 1.2842 | 90MnCrV8 | O2 | ||

| LA 2363 | Z100CDV5 | X100CrMoV5.1 | 1.2363 | X100CrMoV5.1 | A2 | SKD12 | |

| LA 2379 | Z160CDV12 | X153CrMoV12 | 1.2379 | X153CrMoV12 | D2 | SKD11 | |

| LA 3343 | Z85WDCV6.5.4.2 | HS 6.5.4.2 | 1.3343 | M2 | SKH51 | ||

| LA 3247 | Z110DKCWV 9.8.4.2 | HS 4.9.2.8 | 1.3247 | M42 | |||

| LAPM 818 | Z170CDV18.3 | HS 18.1.3 | |||||

| LAPM 2023 | Z130WDCV6.5.3 | HS 6.5.3 | 1.3395 | M3:2 | SKH53 | ||

| LAPM 2030 | Z130WDCVK 6.5.3.8 | HS 6.5.3.8 | |||||

| LA 1050A | A5-1050A | Al99,5 | 3.0255 | Al99,5 | 1050A | ||

| LA 2017 | AU4G-2017A | AlCu4MgSi | 3.1325 | AlCuMg1 | 2017A | ||

| LA 5083 | AG4-MC-5083 | AlMg4,5Mn | 3.3547 | AlMg4,5Mn | 5083 | ||

| LA 7022 | 7022 | AlZn4,5Mg3Cu | 7022 | ||||

| LA 7075 | A-Z5GUP1AZ2- 7075 | AlZn5,5MgCu | 3.4365 | AlZnMgCu1,5 | 7075 | ||

| LA 7000C | 7000 | AlZn4,5Mg1,5 | |||||

| LA 5210 | CuC1 | CW004A | 2.0065 | C11000 | |||

| LAKAL | W Cu | W75Cu25 | |||||

| LAITON | UZ40Pb2 | CuZn40Pb2 | 2.0332 | CuZn40Pb2 | C37700 | ||

| LAITON | UZ40Pb3 | CuZn40Pb3 | 2.0375 | CuZn40Pb3 | C37700 | C3713 | |

| Bronze UE12P | UE12P | CuSn12C | 2.1052 | CuSn12C | C90800 | ||

| Bronze NC4 | UA10N | CuAl10Ni5Fe4 | 2.0966 | CuAl10Ni5Fe4 | C63000 |

Les traitements thermiques réalisés en usine confèrent aux aciers martensitiques un état métallurgique de qualité qui permet leur usinage mécanique.

IL Y A DEUX PRINCIPALES POSSIBILITÉS DE LIVRAISON :

• L’état recuit

• L’état traité

Chacun de ces états requiert de la part de l’utilisateur une gamme de mise en œuvre adaptée.

• L’état recuit : nécessite un traitement de trempe et revenu ultérieurs après usinage ; dans ce cas il est nécessaire d’anticiper les déformations inévitables provoquées par l’opération de trempe et de laisser sur la pièce les surépaisseurs d’usinage néces- saires à la réalisation d’un traitement optimum quant à la structure de l’acier.

Il est également important de veiller à la géométrie des pièces avant trempe et d’éviter les angles afin de pallier au risque de tapure (relaxation de contraintes mécaniques provoquant des défauts ouverts superficiels ou profonds sur la surface des pièces)

• L’état traité : permet de travailler directement à partir de la structure martensitique obtenue en usine. Son utilisation est limitée au niveau de résistance mécanique et de dureté de la matière.

Dans les métiers de l’outillage les nuances sont prétraitées au maximum pour une dureté de 400HB, valeur à laquelle l’usinage est encore réalisable dans de bonnes conditions industrielles.

Les informations techniques données sur les fiches nuances sont des informations générales; nous consulter en cas de besoin particulier.

Températures :

0 degré Kelvin (0k) = -273 degrés Celsius (°C) = -459 degrés Fahrenheit.

0 degré Celsius = 273 degrés Kelvin= 32 degrés Fahrenheit. Pour convertir des degrés Celsius en degré Fahrenheit, il faut multiplier la valeur par 9/5 et ajouter 32.

Pour convertir des degrés Fahrenheit en degrés Celsius, il faut retrancher 32 à la valeur et multiplier par 5/9.

Pression; forces :

Newton (N); Pascal (Pa); kilogramme-force (kgf)

1 Pa = 0,000001 N/mm2 = 0,0000001 kgf/mm2

1N/mm2 = 1 000 000 Pa = 1 MPa = 0,1 kgf/mm2

1 kgf/mm2 = 9,80N/mm2 (1 daN/mm2) = 9,80 MPa (10 MPa)

Mesures :

Millimètre (mm); Pouce (’’) 1 mm = 0,039370’’

1’’= 25,4 mm

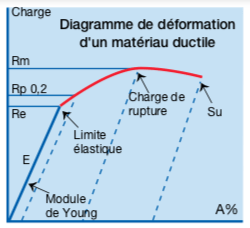

Module de Young : E

Le module d’élasticité est la contrainte de déformation mécanique nécessaire à un allongement de 100 % de la longueur initiale d’un matériau.

Le module d’élasticité est la contrainte de déformation mécanique nécessaire à un allongement de 100 % de la longueur initiale d’un matériau.

Ce cas de figure étant irréalisable sur les matériaux solides,

le module d’élasticité E est défini par la pente rectiligne de la

courbe de déformation où cette dernière est réversible. L’unité de mesure est le MPa ou le N/mm2.

Limite élastique : Re

Elle est définie par un essai de traction sur une éprouvette normalisée et indique l’allongement linéaire d’un matériau entre sa limite élastique réversible et sa charge de rupture.

L’unité de mesure est le MPa ou le N/mm2.

Résistance mécanique : Rm

Elle est mesurée par un essai de traction sur une éprouvette normalisée et indique le seuil de rupture d’un matériau. L’unité de mesure est le MPa ou le N/mm2.

Striction : Z %

La striction est le rapport exprimé en % entre la section nomi- nale de l’éprouvette normalisée et celle de section ultime de l’éprouvette avant rupture.

Allongement : A %

L’allongement est mesuré par un essai de traction sur une éprouvette normalisée et indique la capacité de déformation par étirement d’un matériau avant rupture; c’est le rapport exprimé en % entre la longueur nominale et la longueur ultime de l’éprouvette avant rupture.

Coefficient de poisson : V

Le coefficient de poisson caractérise la contraction perpendiculaire rapportée à l’effort de pression maximum exercé sur un matériau ; il n’a pas d’unité de mesure.

La valeur moyenne pour les aciers est de 0,3.

Densité :

La densité est le rapport entre la masse volumique d’un corps à celle de l’eau pure à 4 °C et à la pression atmosphérique; elle est exprimée sans unité de mesure.

Coefficient de dilatation :

Le coefficient de dilatation thermique est une mesure qui donne la variation du volume d’un matériau à 20 °C et son volume à une température d’utilisation différente (généralement entre 100 °C et 600 °C).

Conductivité thermique :

La conductivité thermique est une mesure physique définissant l’énergie transférée par un matériau en unité de surface et de temps ; elle est exprimée en Watt par mètre Kelvin.

|

LUGAND ACIERS |

AFNOR |

W.Nr |

EN |

AISI/SAE/ASTM |

GOST |

JIS |

GB |

|

S235JR |

E24-2 |

1.0037 |

|||||

|

E335 |

A60-2 |

1.0060 |

|||||

|

LA2067 |

100C6 |

1.2067 |

102Cr6 |

L3 |

WX15 |

Cr12 |

|

|

LA1248 |

XC75 |

1.1248 |

C75 |

Y7-Y |

T7 |

||

|

LA1730 |

XC48 |

1.1730 |

C45+N |

1045 |

45 |

S45C |

45# |

|

LA7225 |

42CD4 +QT |

1.7225 |

42CrMo4 +QT |

4140 |

40XMO |

SCM440H |

|

|

LA2312 |

40CMD8S +QT |

1.2312 |

40CrMnMoS8.6 +QT |

P20+S |

40X2RM-Y |

P20 |

4Cr2Mn1MoS |

|

LA2311 |

40CMD8 +QT |

1.2311 |

40CrMnMo8.6 +QT |

P20 |

40X2RM |

P20 |

4Cr2Mn1Mo |

|

LA2738 |

40CMND8.6 +QT |

1.2738 |

40CrMnNiMo8.6.4 +QT |

P20+Ni |

40X2RHM |

3Cr2NiMo |

|

|

LA400+ |

40CMND8Mod +QT |

1.2738Mod |

40CrMnNiMo8.6.4Mod +QT |

P20+NiMod |

|||

|

LA2714 |

55NCDV7 +QT |

1.2714 |

55NiCrMoV7 +QT |

6LF3 |

5XH2MO |

5CrNiMoV |

|

|

LA2343ESRHH |

EZ38CDV5.1 +QT |

1.2343 ESU |

X38CrMoV5.1 ESR +QT |

H11ESR |

4X5MOC-W |

SKD6 |

|

|

SMV3O |

EZ38CDV5.1 +QT |

1.2343 ESU |

X38CrMoV5.1 ESR +QT |

H11ESR |

4X5MOC-W |

SKD6 |

|

|

APXV |

Z15CN 16.02 +QT |

1.4057 |

X17CrNi 16.2 |

431 |

17X16H2 |

||

|

APX4 |

Z8CND17.04 +QT |

1.4418 |

X4CrNiMo 16.5.1 |

||||

|

LA2316 |

Z35CD17 +QT |

1.2316 |

X38CrMo16 +QT |

420 |

40X16M |

3Cr17Mo |

|

|

LA2099 |

Z7CS13+QT |

1.2099 Mod |

X7CrS13+QT |

416 Mod |

|||

|

LA2085 |

Z30CS16 +QT |

1.2085 |

X33CrS16 +QT |

3Cr17+S |

|||

|

LA2767 |

40NCD16 |

1.2767 |

45NiCrMo16 |

6F7 |

45X2H4M |

45CrNi4Mo |

|

|

819AW |

E35NCD16H |

1.6773 ESU |

35NiCrMo16 ESR |

||||

|

LA2343 |

Z38CDV5.1 |

1.2343 |

X38CrMoV5.1 |

H11 |

4X5MOC |

SKD6 |

4Cr5MoSiV |

|

LA2343ESR |

EZ38CDV5.1 |

1.2343 ESU |

X38CrMoV5.1 ESR |

H11ESR |

4X5MOC-W |

SKD6 |

|

|

SMV3W |

EZ38CDV5.1 |

1.2343 ESU |

X38CrMoV5.1 ESR |

H11ESR |

4X5MOC-W |

SKD6 |

|

|

LA2340W |

EZ35CDV5.1 |

1.2340 ESU |

X35CrMoV5.1 ESR |

H11 ESRMod |

|||

|

ADC3W |

EZ35CDV5.1 |

1.2340 ESU |

X35CrMoV5.1ESR |

H11 ESRMod |

|||

|

LA2344 |

Z40CDV5.1 |

1.2344 |

X40CrMoV5.1 |

H13 |

4X5MO1C |

SKD61 |

4Cr5MoSiV1 |

|

LA2344ESR |

EZ40CDV5.1 |

1.2344 ESU |

X40CrMoV5.1 ESR |

H13ESR |

4X5MO1C-W |

SKD61 |

|

|

ADC88 |

EZ36CDV5.2 |

1.2367 Mod ESU |

X35CrMoV5.2 ESR |

||||

|

SMV5W |

EZ50CDWV5 |

X50CrMoWV5 ESR |

|||||

|

LA2083 |

Z40C13 |

1.2083 |

X40Cr14 |

420 |

46X13 |

SUS420J2 |

4Cr13 |

|

X13T6W |

EZ40CD14 |

1.2083 ESU |

X40CrMo14 ESR |

420 ESR |

46X13-W |

SUS420J2 |

|

|

XDBDW |

EZ100CD17 |

1.3544 ESU |

X105CrMo17 ESR |

440C ESR |

110X17-W |

||

|

X15TN |

EZ40CDVN16.2 |

1.4123 ESU |

X40CrMoVN16.2 ESR |

||||

|

MLX17 |

EZ1CNDAT 12.11.2 |

1.4612 ESU |

X1CrNiMoAlTi 12.11.2 ESR |

||||

|

LA2249 (V300) |

45SCD6 |

1.2249 |

45SiCrMo6 |

45XCO |

|||

|

LA7765 (GKH) |

32CDV13 |

1.7765 |

32CrMoV13 |

||||

|

LA8509 (LK3) |

40CAD6.12 |

1.8509 |

40CrAlV6.12 |

||||

|

LA166 |

16NC6 |

1.5919 |

16NiCr6 |

||||

|

LA2162 |

20MC5 |

1.2162 |

21MnCr5 |

20XR |

20CrMn |

||

|

LA4307 |

Z2CN18.9 |

1.4307 |

X2CrNiMo18.09 |

304L |

03X18H9 |

SUS304L |

0Cr18Ni10N |

|

LA4404 |

Z2CND17.12.2 |

1.4404 |

X2CrNiMo18.12.03 |

316L |

03X17H12M2 |

SUS316L |

0Cr17Ni10Mo2N |

|

LA2842 |

90MCV8 |

1.2842 |

90MnCrV8 |

O2 |

9R2O |

9Mn2V |

|

|

LA2379 |

Z160CDV12 |

1.2379 |

X153CrMoV12 |

D2 |

X12MO |

SKD11 |

Cr12Mo1V1 |

|

LA3343 |

Z85WDCV6.5.4.2 |

1.3343 |

HS 6.5.4.2 |

M2 |

P6M5 |

SKH51 |

W6Mo5Cr4V2 |

|

LA3247 |

Z110DKCWV9.8.4.2.1 |

1.3247 |

HS 2.9.1.8 |

M42 |

SKH59 |

W2Mo10Cr4V1Co8 |

|

|

LAPM2023 |

Z130WDCV6.5.3 |

1.3395 |

HS 6.5.3 |

M3:2 |

P6M5O3-MN |

SKH53 |

|

|

LAPM2030 |

Z130KWDCV8.6.5.3 |

HS 6.5.3.8 |

P6M5O3K8-MN |

||||

|

LAPMAPZ10 |

Z115CDVN19.2.1 |

X115CrMoVN19.2.1 |

|||||

|

LA1050 |

1050A |

3.0255 |

AL99,5 |

1050A |

|||

|

LA2017 |

2017A |

3.1325 |

AlCu4MgSi(A) |

2017A |

|||

|

LA5083 |

5083 |

3.3547 |

AlMg4, 5 Mn0,7 |

5083 |

|||

|

LA7000C |

7021 |

AlZn5,5 Mg1,5 |

|||||

|

LA7022 |

7022 |

3.4335 |

AlZn4,5 Mg3Cu |

7022 |

|||

|

LA7075 |

7075 |

3.4365 |

AlZn5,5 MgCu |

7075 |

|||

|

Cuivre |

CuC1 |

W008A |

|||||

|

LAKAL |

W Cu |

||||||

|

Laiton CuZn39Pb2 |

UZ40Pb2 |

2.0332 |

CuZn39Pb2 |

C37700 |

C3713 |

||

|

Laiton CuZn40Pb3 |

UZ36Pb3 |

2.0375 |

CuZn40Pb3 |

C37700 |

C3713 |

||

|

LAUE12P |

UE12P |

2.1052 |

CuSn12 |

C90800 |

|||

|

LAUA10N |

UA10N |

2.0966 |

CuAl10Ni5Fe4 |

C63000 |

Lugand Aciers

85 route de Château Covet 01100 GROISSIAT

Tel. :+33(0)4.74.81.91.50 | info@lugand-aciers.com

Lugand Aciers est réservé aux professionnels et ne peut proposer ses services et produits aux particuliers. Nous ne pourrons donner suite à leurs demandes. Vente et livraison uniquement en Europe.